The 5-Second Trick For gearbox cvt

The 5-Second Trick For gearbox cvt

Blog Article

A constantly variable transmission (CVT) can be a sort of automatic gearbox, and it operates in Significantly exactly the same strategy to a conventional automatic gearbox from behind the wheel.

The operator adjusts the velocity of your drill by making use of a hand wheel that controls the width with the hole in between the pulley halves. A tensioner pulley is applied in the belt transmission to acquire up or launch the slack during the belt given that the speed is altered.

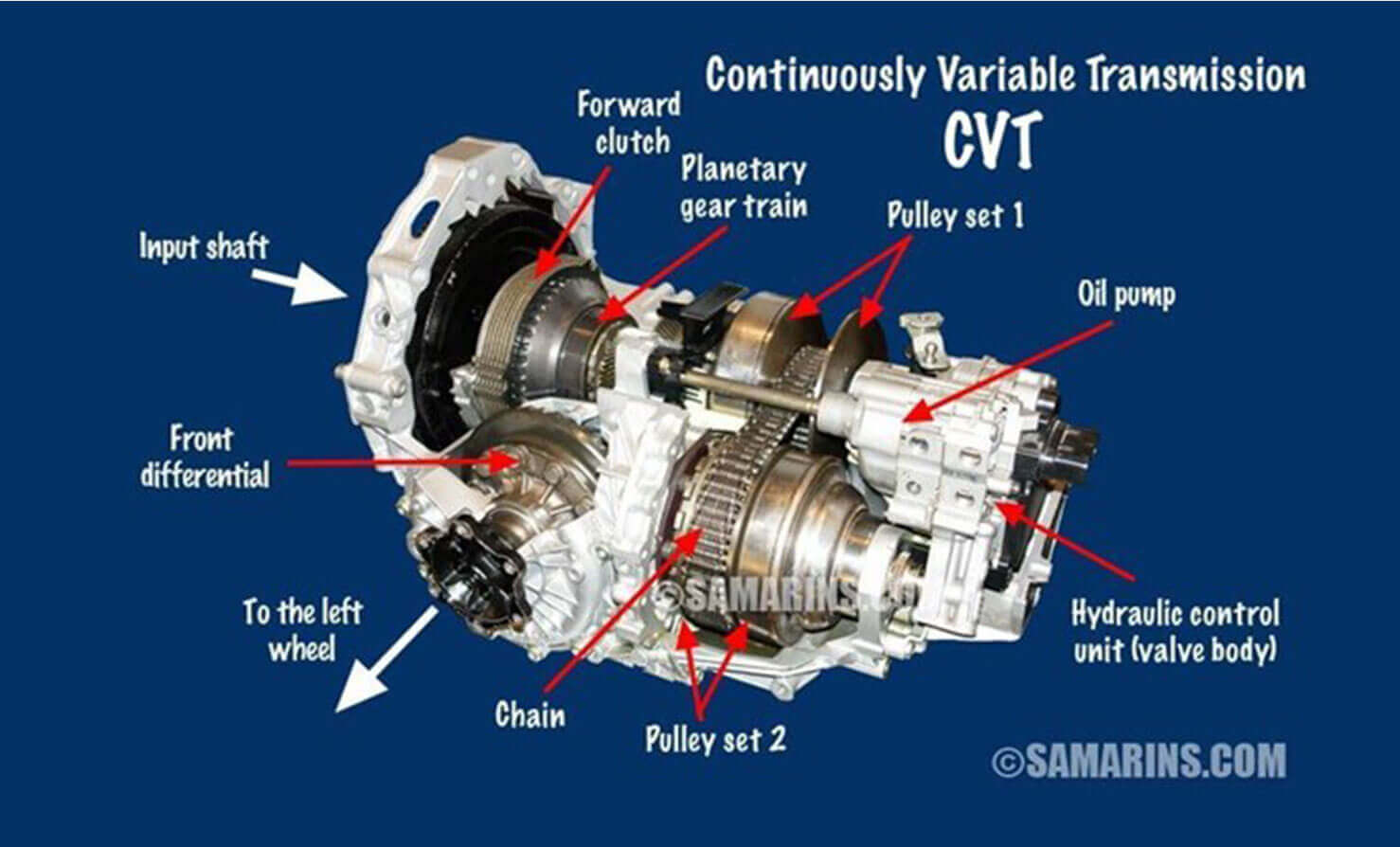

CVTs work by making use of a procedure of pulleys and belts to change the gear ratios continually, permitting the motor to function at a continuing RPM when the vehicle moves at varying speeds.

In a very hydrostatic CVT, the effective "gear ratio" amongst the motor and the driving wheel(s) is the results of a difference between the pump's displacement—expressed as cubic inches or cubic centimeters for each revolution—and also the motor's displacement.

Your browser isn’t supported any longer. Update it to find the greatest YouTube encounter and our newest features. Find out more

Contrary to traditional CVTs, Daihatsu’s D-CVT doesn’t just rely on belt push, but introduces split gears into your combine. As you can see through the cutaway from the D-CVT, there are actually extra gears in addition to a planetary gear set equipped towards the enter and output shafts on the pulleys, with a clutch pack to engage or disengage the latter. In typical Procedure, after you’re pulling off from the stop and travelling approximately very low to medium speeds, the D-CVT capabilities like any other CVT, Using the engine’s torque experiencing a torque converter and to the input pulley, just before currently being transferred to your output pulley by way of a belt and to the wheels.

This permits the engine to work at its most productive amount, leading to better gas economic climate and smoother acceleration.

Guide screw pushed actuators - deliver higher functionality for light-weight or heavy loads at an economical value Belt driven actuators - deliver simple, reliable motion along a longer axis

He's our resident van expert, but covers every little thing from scooters and motorbikes to supercars and shopper items.

Anyway, we have to study why Subaru have picked, evidently illogically, 6 speeds for efficiency and eight for effectiveness. Why not eight for each? The solution lines in the coronary heart in the CVT system. When in performance method, the CVT inside the WRX doesn’t precisely match a rise in revs to a rise in speed.

Doesn’t stage by means of gears. When you strike the accelerator really hard, a CVT doesn’t move via gears Click for more info like a daily automated transmission would, so the CVT has a bit of a Mastering curve.

One more quirk from the DAF procedure was the cars and trucks it had been fitted to didn't have a reverse equipment, rather the CVT box simply just worked in reverse, so in principle these vehicles experienced a leading pace that was achievable heading both backwards and forwards.

While such a procedure appears greatly various, each of the components are analogous to a belt-and-pulley technique and bring on the exact same success -- a constantly variable transmission. Here is how it really works:

A constantly variable transmission system is usually a style of automated transmission by which an arrangement of pulleys and belts made it probable for the generate to obtain n-variety of steady equipment ratios in a range (will depend on the design).